Hornady Lock-N-Load AP Press Info

Contents

Overview

The Hornady Lock-N-Load Auto Progressive is a 5-station progressive reloading press.† Each of the five stations is equipped with Hornadyís Lock-N-Load quick-change bushing system, which allows dies to be installed or removed with a simple 1/8 turn.† Itís quick and allows dies to be swapped in and out of all five stations quickly.††

The press automatically advances the shell plate with each pull of the handle.† The shell plate advances 1/10 of a turn on the upstroke, and 1/10 of a turn on the downstroke (half an index going up, and half an index going down).† This gives it a nice smooth stroke, and also allows priming to occur on the downstroke between stations 1 and 2.† The cases are retained in the shell holder by a circular coil spring, which is easily moved out of the way to remove or insert a case at any station.

Spent primers are sent down a tube that can be routed into your choice of receptacle Ė a trashcan or what-have-you.† This works extremely well with zero mess.†

The press comes with Hornadyís Lock-N-Load powder measure and case-activated powder drop system.† An automatic case feeder is optional.†

Powder Measure

The included powder measure is Hornadyís Lock-N-Load powder measure.† It uses the standard Culver-type rotating drum with a screw adjustment for charge volume.† Itís very similar to the RCBS Uniflow.† The Hornady measure uses quick-change metering inserts (hence the Lock-N-Load name).† This lets you use different types of metering inserts, or keep a metering insert set for each caliber you load.† The measure comes with one standard insert, which is suitable for rifle or large pistol charge weights.† Inserts with micrometer adjustments are available in rifle and pistol sizes.† There are also high-capacity inserts (up to 265 grains) for loading .50 BMG.† As of this writing it appears that Hornady is phasing out the pistol micrometer (which fits in the standard drum that comes with the measure) for a dedicated pistol drum and accompanying insert.†

So far I have not had occasion to use the pistol insert.† I have been loading rifle cartridges and large pistol cartridges like .357 and .44 Magnum with fairly large powder charges, so the smaller insert has not been needed.†

The measure itself has been fairly accurate.† With a fairly fine-grained powder like 2400, it routinely throws charges within .1 grain of the target weight.† With extruded rifle powders like IMR-4895 it gives me +/- .25 grain consistency.† With powders like this I do get the occasional chopped kernel and it doesnít operate as smoothly.† Iíve also used the oddly-shaped IMR Trail Boss powder, which doesnít meter as well as 2400 but is better than the extruded powders.

The case-activated powder drop system included

with the press comes with bushings that cover both pistols and rifle

cases.† It is easy to adjust and has

worked well for me.† Extra powder die

assemblies can be purchased (about $12-13) so that a powder die can be

dedicated to each caliber.† If you also

keep a preset metering insert for each caliber, this eliminates adjustments

when switching calibers.

Priming System

Apparently the original priming system on this press left a lot to be desired.† Hornady revised the priming system, and my press came with the redesigned priming system (as should all LnL AP presses beyond serial number 7000.† Mine is in the 9200 range).† I have had no serious trouble with it over the course of several months of use.

Since the shell plate rotates half an index on the upstroke and half an index on the downstroke, the press primes on the downstroke between Station 1 and Station 2.† A slider moves back and forth via a cam wire and picks up a primer from the feed tube at the top of the stroke.† It then delivers the primer to the priming punch on the downstroke, and the primer is seated at the bottom of the stroke.

Changing from small primers to large primers or vice versa is easy enough and only takes a few minutes.† The feed tube is removed, which exposes the primer slide.† The primer slide is swapped out and the feed tube is replaced with the appropriate size.† The priming punch is then changed from beneath the subplate.† The only tools that are required are a hex wrench for the feed tube and an open-end wrench for the primer punch.

Case Feeder

The case feeder for this press can handle both rifle and pistol cases.† The feeder comes with parts for both large and small diameter cases (small diameter maxing out around .357 Magnum size).† Small pistol, large pistol, small rifle, and large rifle feed plates are available.†

The case feeder requires a little bit of tweaking to get set up, but in my experience it doesnít need any more adjusting once itís set properly.† Changing from one size case to another means swapping a few parts, which does take a few minutes but isnít too difficult.

The feed mechanism is actuated by a cam wire in the same manner as the priming slide.† At the top of the stroke a case is dropped onto the subplate, and then the case is pushed into the shell plate on the downstroke.

The case hopper is generously sized.† Itíll hold at least several hundred .308 sized cases, or well over a thousand large pistol cases.† Suffice it to say that Iíve never needed more capacity.† The drive motor has quite a bit of torque and I havenít had problems with it bogging down.

Caliber Changes

In order to change calibers with this press, obviously the first thing to do is change out the dies.† With the Lock-N-Load bushings, this is simple.† If you donít have a powder die for each caliber, youíll have to adjust the powder die.† To do this you put a case in that station and run the ram to the top, then adjust the powder die so the measureís handle is just short of the top of its stroke.† If the shell plate needs to be changed, it can be done quickly with a single bolt.† Priming system changeovers are as explained earlier.† Generally this only takes a few minutes, and the only tools required are hex wrenches for the powder die lock ring and primer feed tube, and a small wrench for the primer punch.

The case feeder has its own set of parts that might need to be changed if you are switching from a small-diameter case to a large-diameter case.† The feed tube, and a couple bushings in the feed mechanism need to be changed.† The feed fork on the feed mechanism usually has to be changed.† The feed tube height needs to be adjusted for the length of the case.†† The appropriate feeder plate must be installed. In my experience the timing does not need to be adjusted once itís set initially.† It usually takes a little time to get everything switched over, but you easily make that up with the extra speed the case feeder provides.

Downsides

I have noticed some shortcomings:

- Canít expand and drop powder in one station.† This is being addressed with a new case-activated powder drop system.† At the time of this writing (June 2006) the new system is expected any day now.† Those with the old system can also adapt Lyman powder-through expanders to the Hornady CAPD.† More on that later.

- The case ejection wire interferes with dies in Station 5.† Because of the way the press indexes, the wire that ejects rounds at the end of the loading cycle gets in the way of any die that hangs below the top plate of the press.† This is difficult to describe so Iíll let the photos do the talking.† To get around this, some users have modified their dies to clear the wire.† Itís also possible to operate the press without the ejector wire and simply push rounds out by hand.† Hornadyís crimp dies are reportedly shorter in order to avoid this problem, and the new expanding case-activated powder drop will also open up a station to help with this problem.

- Thereís no low primer warning system.† Since the feed tube isnít transparent, itís hard to know when youíre getting low on primers.† My low-buck solution is a piece of 1/8Ē wooden dowel with a flag made of tape.† When the flag hits the top of the feed tube, I know Iím out of primers.† I think the Dillon warning system can be made to work on this press, and Iíve ordered one to try.

- The priming system is susceptible to debris.† Iíve had spilled powder and other gunk get into the primer slide area and bind up the slide.† A shot of compressed air usually cleans it right out.† Iíve also learned how to tell by feel when this is happening and keep it from causing trouble Ė itís possible to bend the cam wire and break the slide if you force it.

Comparisons to other presses

The Lock-N-Load AP is most often compared to the Dillon RL 550B.† The RL 550B has four stations and the shell plate is indexed manually.†† The LnL has five stations and automatically indexes.† Both presses have optional case feeders; however at the time of this writing the 550ís case feeder only handles pistol cases.†

Comparisons are also made with the Dillon XL 650.† The XL 650 has five stations, automatically indexes, and has a fully functional case feeder option (both rifle and pistol).† In my opinion the Lock-N-Load AP is more comparable to the XL 650 than the RL 550B due to the auto-index and rifle/pistol case feeder.

The nice thing about the Lock-N-Load AP is that itís priced close to the RL 550B, but when the case feeder is added it is capable of producing ammo at a rate closer to that of the XL 650.† The case feeder for the 550 is hamstrung by the 550ís lack of automatic indexing.†

The biggest difference between the Hornady press and the Dillon presses is the way dies are held in the press.† The Hornady press uses a Lock-N-Load bushing for each individual die.† The Dillons use a toolhead that holds all the dies for a given caliber.†† Dillonís toolhead approach will give faster caliber changes if you buy a dedicated powder measure for each toolhead.† The quick-change inserts for the Hornady powder measure make that less of a necessity for the Hornady press Ė just buy a metering insert and a powder die for each caliber.† Even better, you can have multiple inserts for different loads in each caliber.† I personally like the flexibility of the Lock-N-Load bushings.† They let you pull any die out of the press, and you arenít tied to a particular configuration of dies in a toolhead.† I also like the ability to snap any given die into my single-stage press.

Another difference is the powder measure.† The Hornady powder measure is very good and works well with a wide range of powders.† The Dillon measure uses charge bars and doesnít work as well with some powders (extruded powders in particular).

Tips, Tricks, and Accessories

Iíve found a few items and techniques that enhance the use of my LnL press:

- Hornady die lock rings.† These lock rings are the split type that lock by tightening around the die, not by driving a setscrew into the die threads.† Theyíre easy to adjust and stay where you set them, so even if youíre not using Lock-N-Load bushings you can remove and re-install a die without losing your settings.† The rings also have wrench flats on them.† I buy these and put them on dies that come with lesser lock rings.

- Hornady die wrench.† This wrench has slots to fit the Hornady lock rings and the adjustment stems on their dies.† It makes it easy to get the dies tightened into the LnL bushings Ė tighten the lock ring on the die, then use the wrench to turn the lock ring into the bushing.

- Hornady die boxes.† Most of the storage boxes that come with non-Hornady canít handle dies with LnL bushings installed.† The Hornady die boxes are larger and will fit most dies with the bushings installed.† Theyíre available separately from MidwayUSA.

- Hornady reloading dies.† Since Iíd end up buying the lock rings and die boxes anyway, I just buy the Hornady dies and they come with those accessories.† The dies themselves are quite nice too.† The seating dies have a sliding sleeve for good bullet alignment, and can be upgraded with a micrometer seating depth adjustment.† Theyíre also easy to disassemble for cleaning.† The rifle sizing dies have a nice elliptical expander ball that works well on dented case mouths.† I like the titanium nitride sizing ring on the pistol dies.† The pistol die sets come with seating stems for round-nose and flat-point bullets (at least, the .357 and .44 sets do).

- Frankford Arsenal Vibra-Prime primer tube filler.† This handy gadget will fill a primer tube in seconds and is money well spent.† The primer pick-up tubes supplied with the press are functional, but terribly slow.† Contrary to the info on Midwayís site, this tool works straight out of the box with the LnL APís priming system (Midway says you have to modify the feed tube, but I think theyíre talking about the old style priming system).† I fill up the Vibra-Primeís tube and then load the primer feed tube on the press straight from there.† If youíre loading in volume, get extra tubes for the Vibra-Prime and load them up beforehand.

- RCBS powder measure baffle.† The baffle for the RCBS Uniflow will fit the Hornady measure with a little tweaking.† The baffle helps keep the volume of powder above the drum more consistent.

- Hornady powder drain insert for the LnL powder measure.† Without a baffle in the measure, itís easy to just pull the measure out of the press and pour the powder out of the hopper.† With the baffle installed, itís a little tougher to get all the powder out.† With the drain insert you just pop it in and the powder flows out through the drum, without removing the measure from the press.

- Get good hex wrenches.† Most of the fasteners on this press require hex (aka Allen) wrenches.† I use a set of Bondhus ball-end wrenches.† A small Crescent wrench is just about the only other tool you need to work on this press if you have the Hornady die wrench.† FYI the nuts & bolts on this press are all inch, not metric.

- Keep everything tight.† This goes without saying, but there are a couple places to keep an eye on.† There are two bolts that secure the subplate to the ram.† Iíve had them work loose on me, so I used blue Loctite on them and theyíve stayed put.† Also keep an eye on the bolt that holds the shell plate.† Iíve found that cases wonít line up properly with the die mouths if this bolt gets loose.

- Upgrade the case-activated powder drop with Lyman powder-through expanders.† Some handy folks on the Internet have found a way to modify the Hornady CAPD system so Lyman powder-through expanders can be installed.† This post at The Firing Line details the modifications required.

- Modify a water bottle cap to make a spent primer catcher.† I like the way the spent primers are handled with this press, but the trashcan under the press was getting in my way.† I made some cuts to a water bottle cap so that the spent primer hose would fit tightly.† Now the water bottle just hangs on the end of the hose and doesnít get in the way.

- Get the Hornady Lock-N-Load conversion bushing for your single-stage press.† I have the conversion installed in my Lee Classic Cast press (an excellent machine, by the way) so I can use my dies in that press without removing the Lock-N-Load bushings from the dies.† If your press can take 1-1/4Ēx12 dies (the RCBS Rock Chucker and other high-end presses qualify) the conversion bushing installs in seconds.

- Shell plates for the ProJector do not work with the LnL AP.† They lack a bevel on the edge for the case retaining spring.† New shell plates from Hornady will work with either press, but if you are buying used you will want to make sure that itís a LnL/ProJector plate and not just a ProJector plate.

Photos

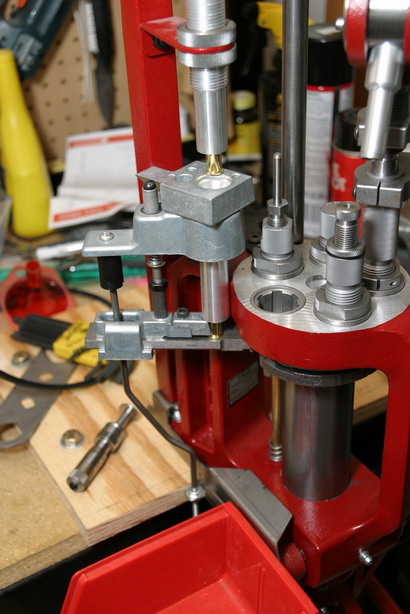

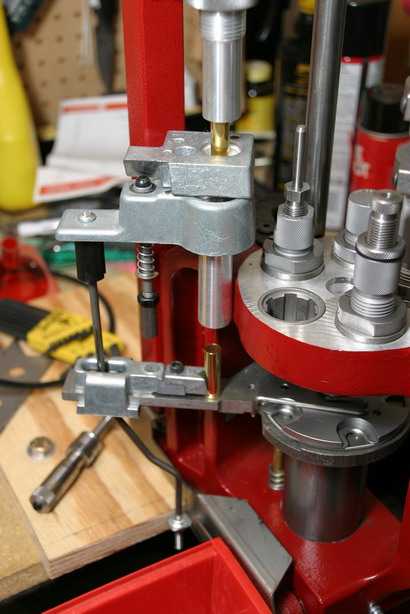

The priming system:

The primer feed tube removed to expose the primer slide, shown here at the top of the stroke:

The primer punch is removed by unscrewing the hexagonal bolt from the bottom of the subplate.† The bolt in the side of the ram is one of two that I had to use Loctite on.

This sequence shows the case feeding mechanism in action.† A case drops onto the subplate at the top of the stroke, and the feed assembly pushes the case into the shell plate on the downstroke.

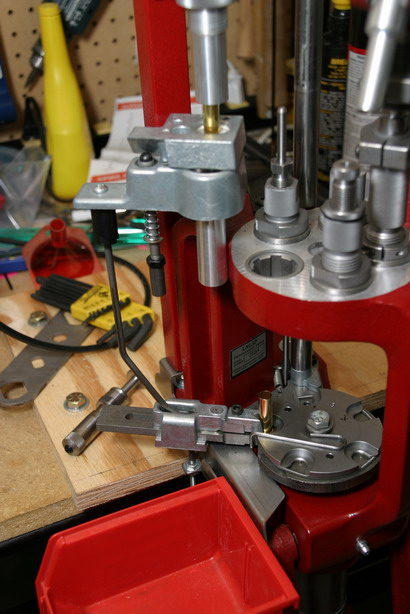

These photos show the problem with the ejector wire and Station #5.† The first shot is the position of the shell plate for Station #5.† The ejector wire can be seen intruding into the space for the die.† The second shot shows the wire contacting the bottom of a Redding competition seating die.

My low-cost primer warning system:

A set of Hornady dies for .44 Special/Magnum.† Note the Lock-N-Load bushings, split lock rings, large die box, and extra seating stem.

The Lock-N-Load conversion bushing installed in a Lee Classic Cast single-stage press.